SA electromechanical firm steadily growing its international presence

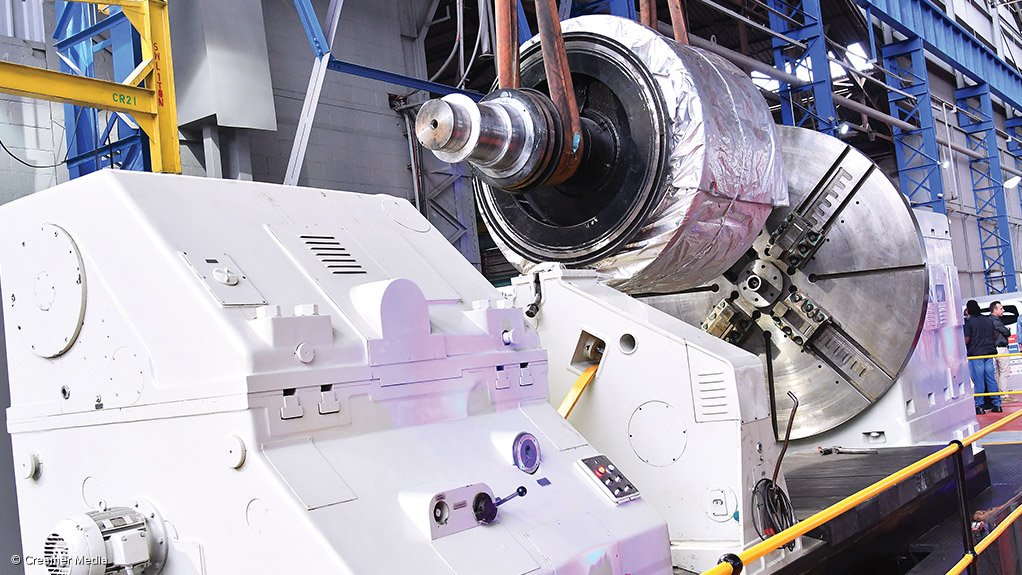

140 T LATHE The new 140 t CNC lathe in the Benoni workshop

Photo by Dylan Slater

ROTOR CLEANROOM The division performs repairs and refurbishment of rotors and stators

Photo by Dylan Slater

Local electromechanical service provider Marthinusen & Coutts continues to receive service and repair contracts locally, in Africa and internationally, and expects demand for its outsourced services and maintenance offerings to continue to grow, says Marthinusen & Coutts marketing executive Mike Chamberlain.

Marthinusen & Coutts, which is a division of electromechanical equipment company Actom, attributes its success to its people. The quality of the teams’ work with rotating electrical equipment, motors and generators frequently leads to original-equipment manufacturers (OEMs) and large multinational companies tapping the company for installations, in-field services and repairs, and off-site refurbishments, he says.

About 525 people are employed at its South African operation, as well as 100 more in Zambia, Zimbabwe, and Namibia. Its field service teams are diversely skilled and deployed across its operations, based on the requirements and expertise of its personnel. Its Cleveland facility, in Johannesburg, also hosts in-house design and engineering offices that provide expert support for its service teams.

The division also continues to invest in its infrastructure, and has added a 140-t lathe to its 14 000 m2 Benoni factory to repair large rotating components such as generator rotors, turbines and large fans. The new lathe allows for work on pieces up to 40 t in weight and 10 m in length. The machine has a 3.2 m swing and has been upgraded from semiautomatic to fully computer numerically controlled with precision tolerances.

The facility, one of seven workshops in Southern Africa, also has clean rooms for rotor and stator refurbishment and assembly.

The division has repaired or refurbished motors larger than 100 MW, including the stator and rotor of a 373 MW, 14-pole motor- generator for the Ingula pumped-storage scheme, in KwaZulu-Natal. This work was done for multinational engineering group Voith. However, the division has found a good niche in the 100 MW range, says Chamberlain.

“We have also installed a 150 MW Skoda Doosan turbine and Siemens generator for Minera opencast copper mine, in Panama.

“Our partnerships with OEMs, and the references of our previous work, are helping us to gain work worldwide. While Africa is expected to remain the key market for us, we expect to see the outsourced service market demand grow within and beyond Africa,” he says.

Chamberlain lauds the Marthinusen & Coutts teams, highlighting the meticulous work needed to replace coils of high-speed rotors and ensure the insulation is soundly in place as an example. Removing and then replacing the coil retaining rings are similarly challenging because they have to be removed using special equipment, without damaging the windings, and then replaced, which involves heating and placing them accurately before they cool and contract.

“Coil retaining rings are usually used on machines that operate above 3 000 rev/min. If a coil ring fails, you can find the pieces up to a kilometre away. Obviously, this is dangerous to personnel, and the reason why there cannot be any defects in the ring, or improper repairs.”

Chamberlain highlights another technical project to repair and refurbish a 3 000 rev/min, 36 MW motor that drives a compressor. The motor had been installed more than 20 years ago and developed problems where electric arcing on the rotor bars was causing wear.

The division’s engineering team redesigned the dovetail joint and changed the profile of the bars by machining slots into them. This eliminated the problem and the machine was refurbished and put back into operation, explains Chamberlain.

“We are able to provide expert maintenance and service support, as well as design services, for large multinational companies and OEMs. These companies see the logic of leveraging us to eliminate shipping the machines back to their factories, improving the outcomes for their clients,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation